Zhejiang Dibei Electric Co., LTD. (Stock code: 603320) is a national high-tech enterprise and a specialized, refined, distinctive and innovative enterprise dedicated to the research and development, manufacturing and sales of high-efficiency motors and drive controllers. It is committed to providing energy-saving, low-carbon and environmentally friendly system solutions. With an annual production capacity of over 20 million sets and sales of 1.2 billion yuan, our global market share in the niche field is nearly 10%. We have established strategic partnerships with well-known domestic and foreign brands such as Danfoss, Huayi Group, and Invate.

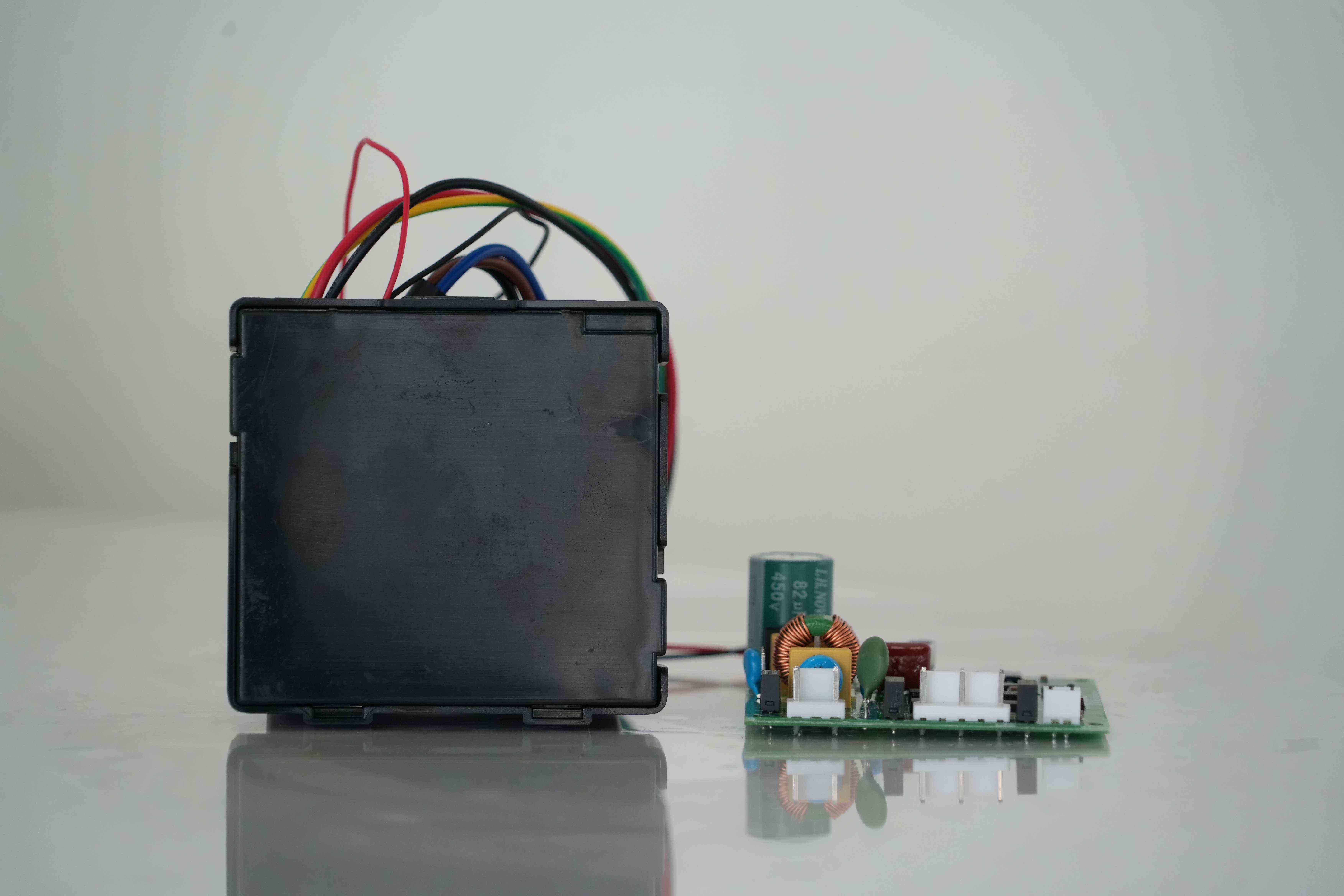

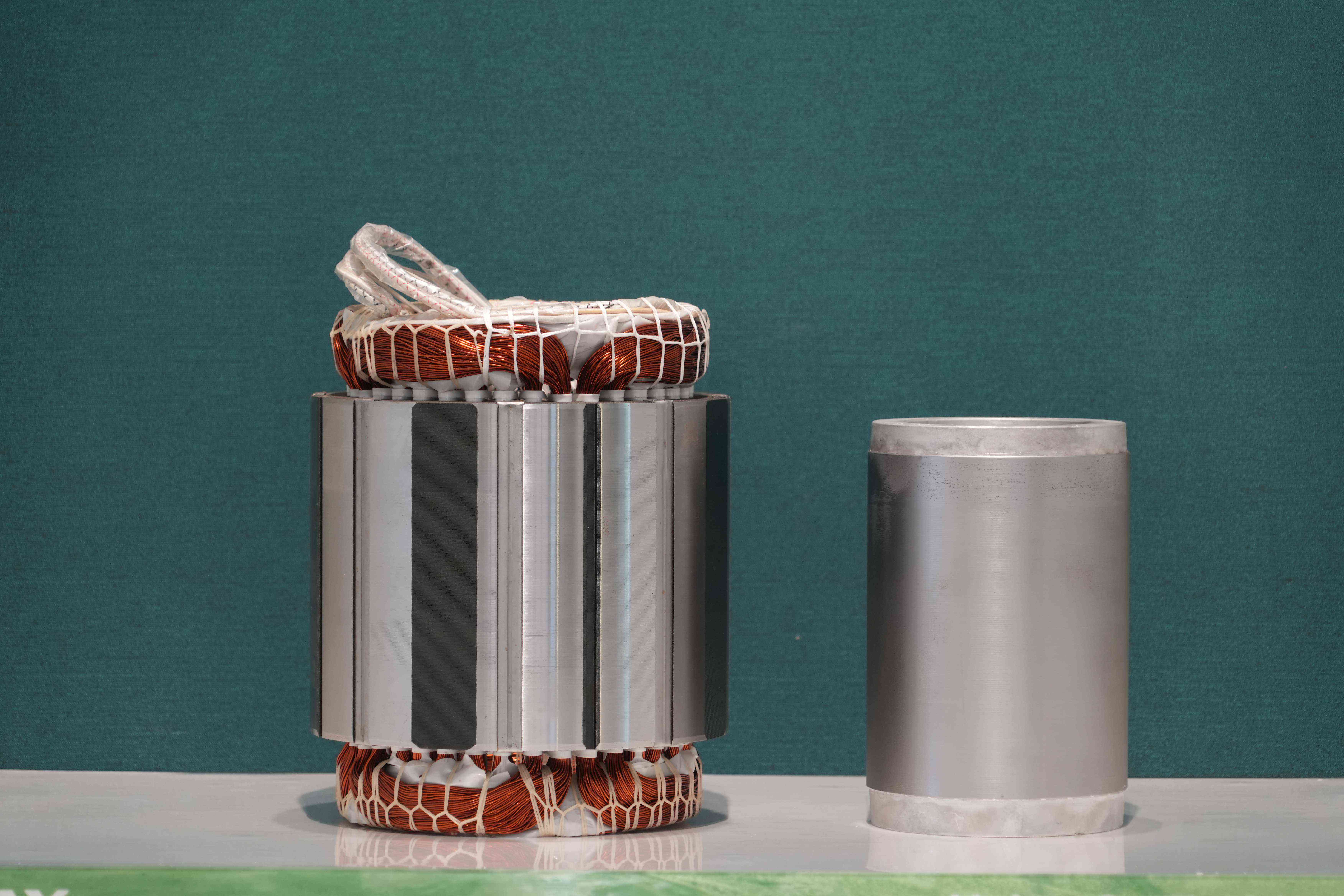

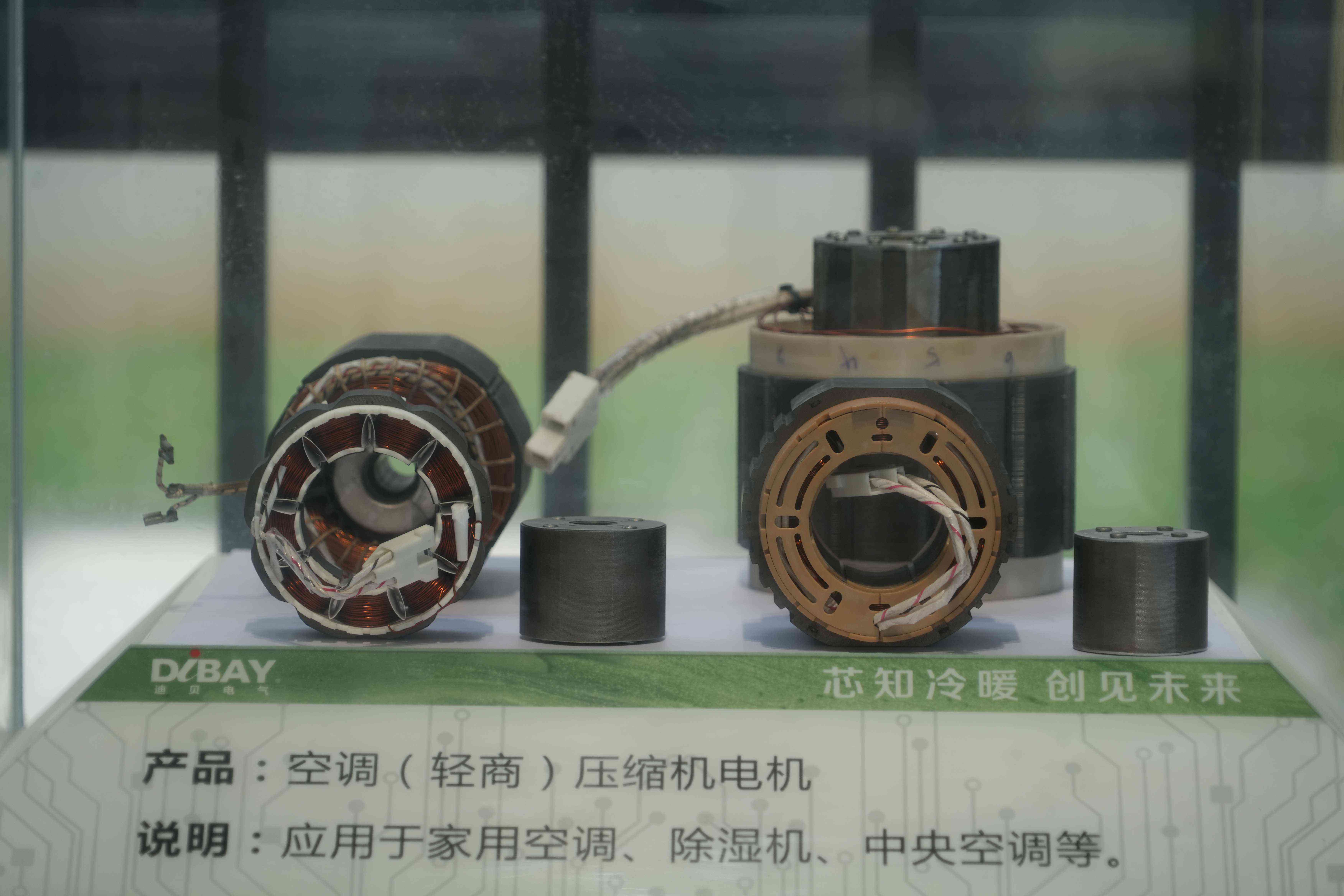

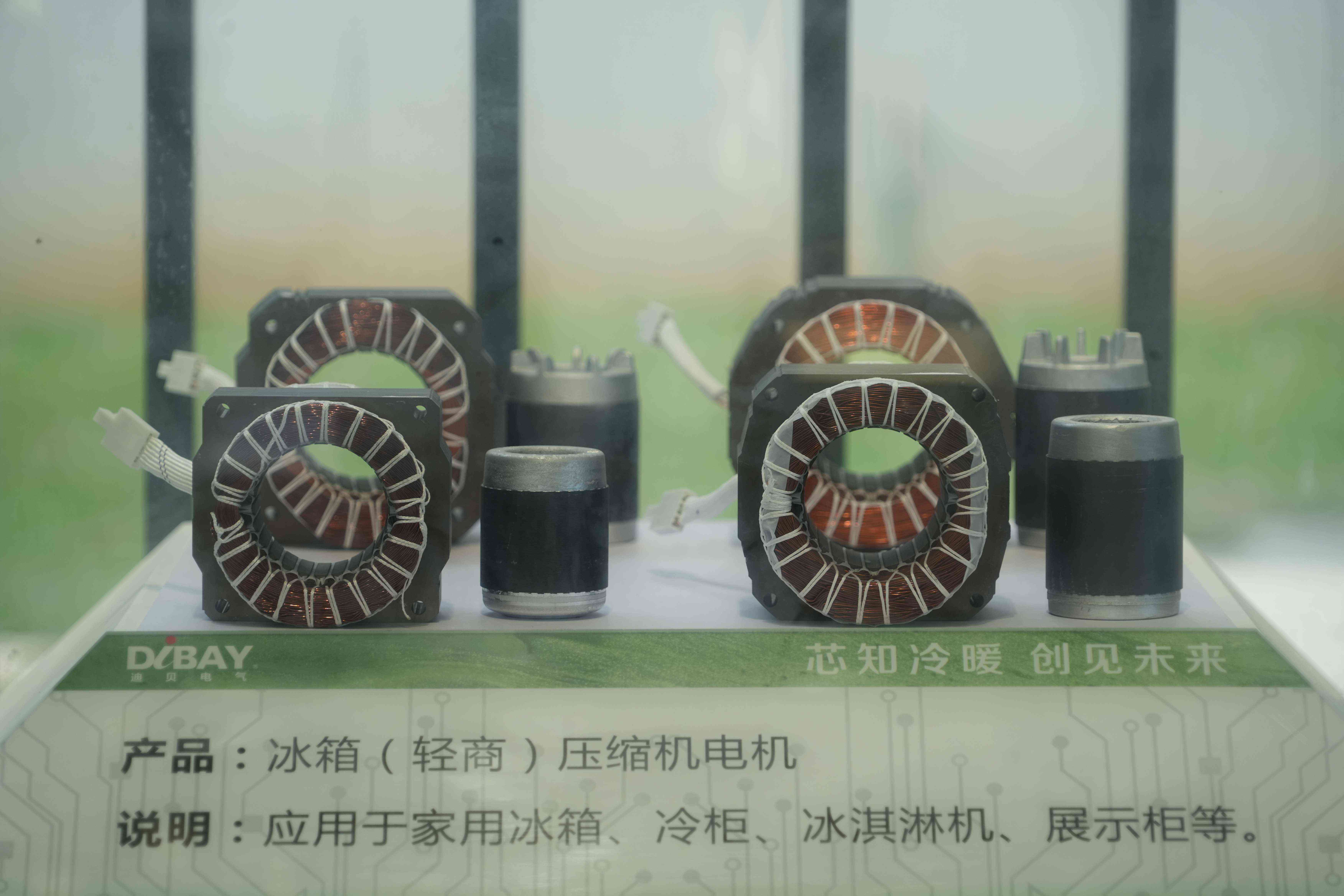

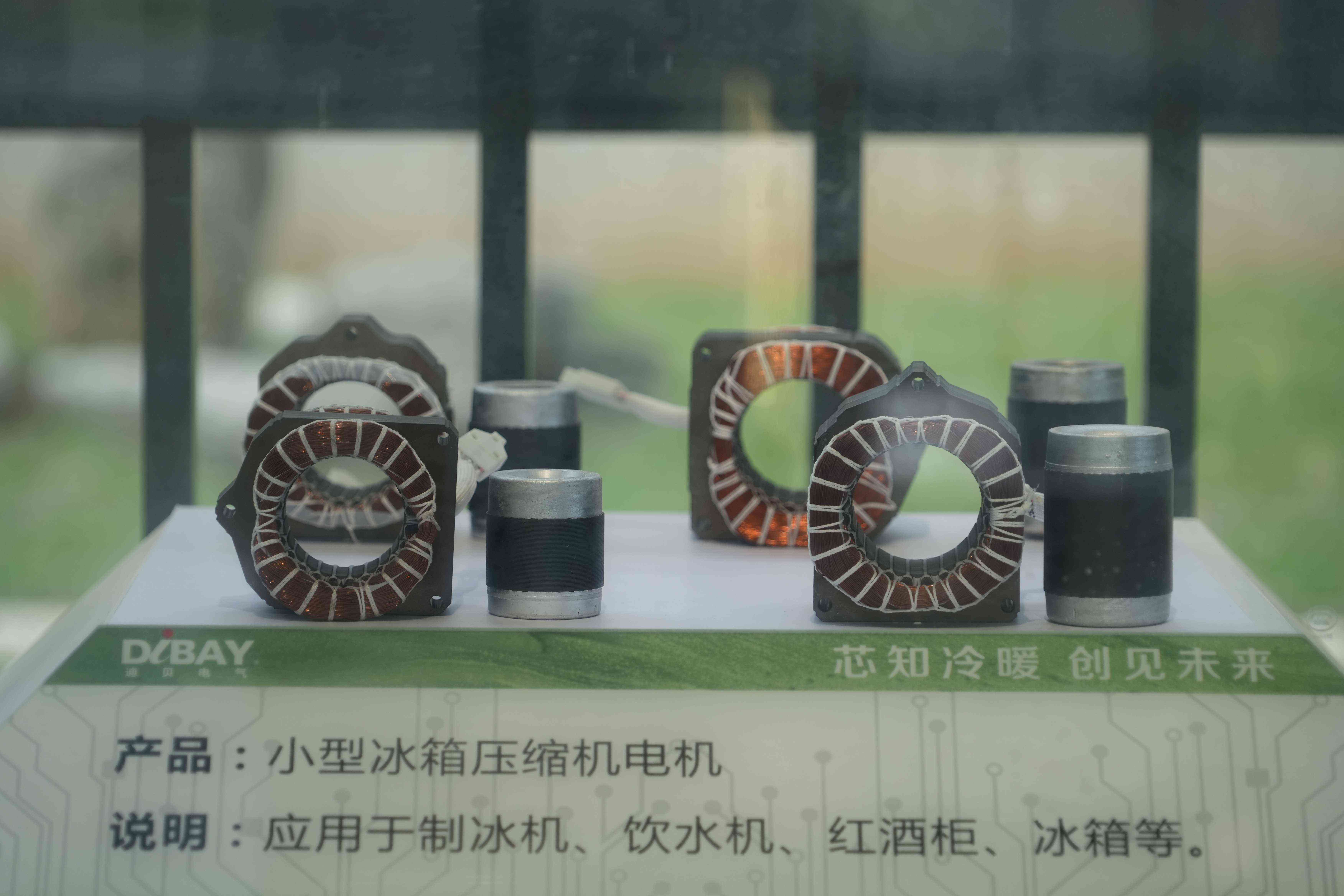

With over 30 years of dedication to the motor industry, our core products cover various types of compressors for industrial, commercial and household use, including piston, rotor, scroll, semi-hermetic and screw compressors. The terminal applications cover multiple fields such as air conditioners, refrigerators, cold chain transportation, thermal management systems for new energy vehicles, and thermal management systems for energy storage. It is the supplier and service provider with the most comprehensive product range in the industry.

In 2021, the industry's first brand-new intelligent factory was completed and put into operation, achieving refined and intelligent management throughout the entire process of planning, manufacturing, transportation and warehousing.

In the field of scientific research, a provincial high-tech research and development center and a postdoctoral workstation have been established, and an experienced R&D expert team has been formed to achieve full-process development capabilities covering design, simulation and testing. It holds 16 invention patents and 75 utility model patents. It has consecutively won multiple honors such as "Top 30 Industrial Enterprises", "Shaoxing City Enterprise Technology Center", "Outstanding Contribution Award for Economic Development - Top 30 Industrial Enterprises", and "Top 20 Taxpayers in the Industrial and Commercial Sector of Shengzhou City".

"Talent is the source of hope for Dibe." Through measures such as establishing internship bases for college students, deepening school-enterprise cooperation, strengthening internal intermediate and advanced skills training, and building a complete career development channel, it has taken multiple measures in selection, appointment, training, and assessment, gradually establishing a high-quality cadre team and reserve team. In the future, Dibe will leverage its technological innovation and R&D capabilities to explore the path of transformation, striving to become a leading global enterprise in sealed motors. It aims to create a sustainable development pattern featuring a full range of products, strong technology, and robust manufacturing, achieving "one full and two strong" capabilities. This will contribute new quality productivity to the high-quality development of the industry, enabling "Made in China" to benefit the world and jointly build a bright future.

The basic period of entrepreneurship from 1989 to 1995

The period of business improvement from 1996 to 2010

Strategic Development period: 2011-2021

The period of transformation and leap from 2022 to 2030